In recent years, with the continuous optimization and development of domestic computer applications in graphics and special materials in manufacturing, 3D printing has gone from the past fantasy to reality. Nowadays, 3D printing has been gradually introduced into various fields of production and manufacturing.

With the vigorous development of cultural and creative industries, product design that simply meets the function has long been abandoned by the times. Product design that is function oriented has played an important role in the design stage for a long time.

At the same time, it also exposes more monotony and tedium, hiding the attributes and characteristics of design. Product function, product appearance, product concept, product structure and other factors are interdependent, interrelated and inseparable.

In the lighting design industry, 3D printing has important applications. Lighting design is an important field in the manufacturing industry, which has both artistic and practical responsibilities. At present, the technology of various lamp manufacturers is basically the same, and the core of competition is creativity.

3D printing is an innovative content in the teaching of lamp design, which shortens the time for lamp designers to turn design concepts and specific graphics into specific products, and effectively improves the production efficiency of manufacturing enterprises. Therefore, 3D printing has an important application in the manufacturing industry, and its development prospects are broader.

Lamps have a history of thousands of years in China. Since ancient times, it has a profound cultural heritage, which provides inspiration for current people engaged in lamp design. At present, domestic lighting design is generally in the industrial field and education industry.

In the field of education, teachers generally teach the design concept of lamps and lanterns, and then students freely design lamps and lanterns, and finally make this design into a finished product. It is difficult to understand the specific design concept of lamps and lanterns if we did not see the finished products in the past.

This has a long cycle from design, drawing to manufacturing. At this stage, the design of traditional lamps can no longer adapt to the development of modern science and technology, and a single lamp can no longer meet the needs of modern people. The traditional design mode of lamps and lanterns can no longer provide people with the required teaching environment and foundation.

The previous design forms can improve students' imagination and thinking ability in design, and can also improve the entry standard of lamp designers. The application of 3D printing in the teaching of lamps and lanterns can improve their technical level, open up students' imagination and improve their thinking ability.

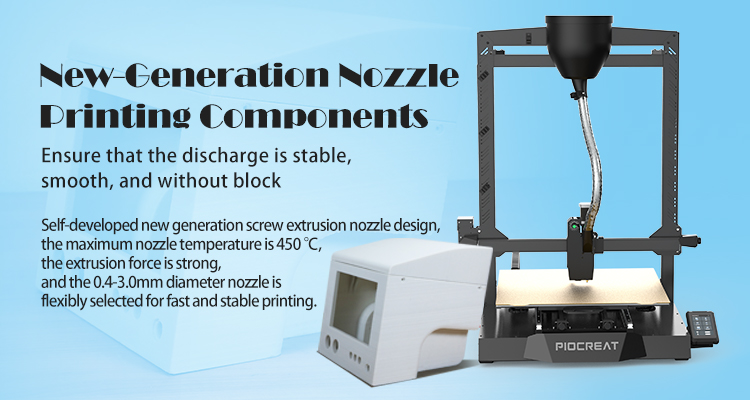

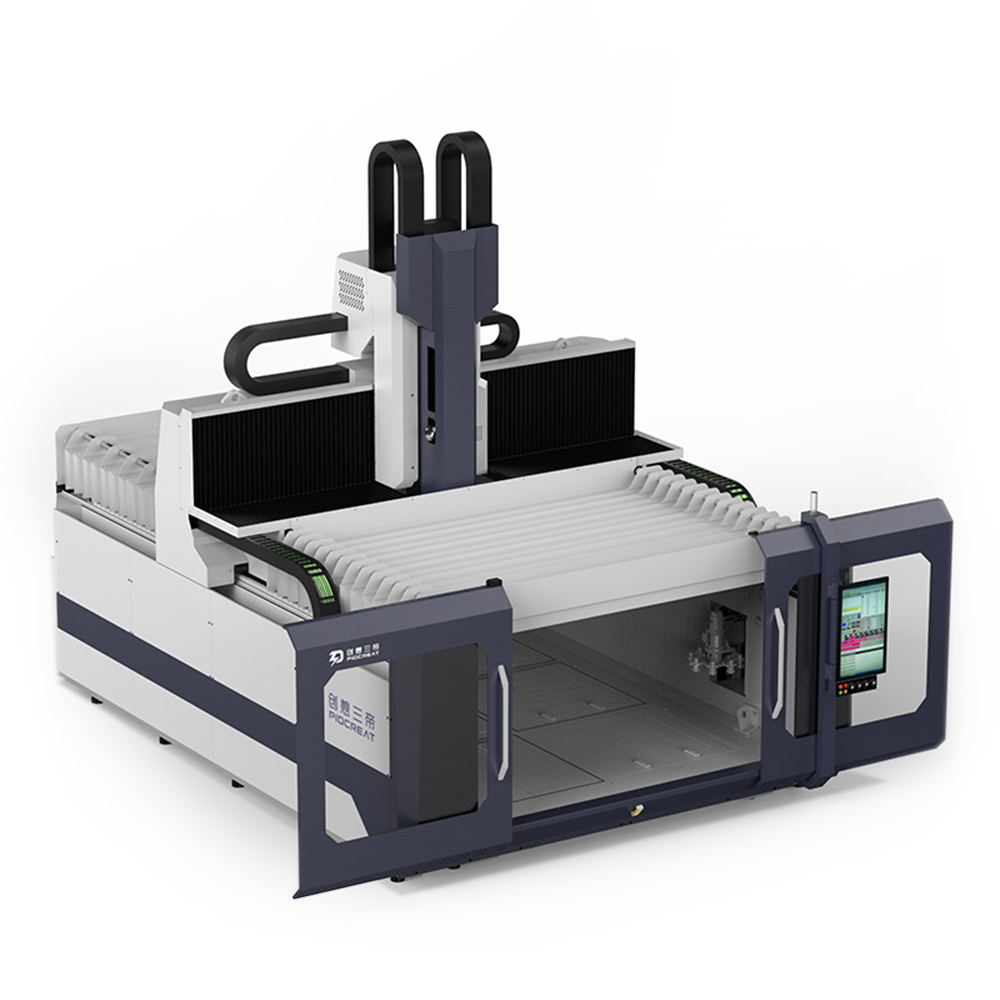

3D printing relies on 3D manufacturing related software, which can directly manufacture 3D graphics in the computer through direct connection with the computer. 3D printing can be modified during the manufacturing of objects to make the final objects more interactive.

In a narrow sense, 3D printing improves the efficiency of the manufacturing industry. However, from an artistic perspective, 3D printing breaks through the traditional drawing method. Through the integration of computers and integrated systems, 3D images in computers can be directly printed without adding additional mold manufacturing, which reduces the production costs of enterprises.

3D printing does not need to be manufactured manually, and is completely automated by computers and manufacturing systems. Therefore, 3D printing is a major change in industrial production. 3D printing is a subversion of the concept. It directly separates the product from the production line. It can be completed in a few simple steps from creativity to molding.

For example, a designer can design a three-dimensional lampshade in a computer, which can be directly connected with a printer and manufactured. Now in the teaching of lamp design, the school has gradually introduced three-dimensional software to assist teaching, which makes teaching more flexible.

Introducing 3D printing into the teaching of lamp design is an innovation in teaching. 3D printing is a new concept in the field of design and manufacturing. 3D printing can improve students' interest in design after class.

Teachers can complete the teaching content specified in the classroom through students' interests, so as to create the overall atmosphere of the classroom. The introduction of 3D printing in teaching has broken the previous form of passive education for students, enabling students to actively explore the new technology of 3D printing. Teachers can use this to effectively carry out classroom teaching.

For example, teachers can add appropriate experimental links in the classroom and make lamps on site. Teachers can evaluate students' design according to the finished product. Compared with the previous single drawing design, 3D printing provides students with more opportunities to practice. Students can design in their spare time and use 3D printing to make it, so as to enhance their ability to design lamps.

Due to space constraints, 3D printing is rarely used in the classroom of current lighting design, but it has long-term significance. Teachers can improve students' basic literacy in design through 3D printing.Lighting design is a relatively comprehensive subject, which requires students to have a certain theoretical knowledge, but also a certain quality in art.

The application of 3D printing can help students improve their accomplishment and ability in these two aspects, increase their opportunities for practice, and enhance their ability to practice. 3D printing effectively promotes students' commercialization of lamp design from creativity to finished products, and can make students' design works meet the requirements of modern enterprises and society.

Therefore, 3D printing effectively promotes the accumulation of practical experience of students in school. The domestic 3D printing technology is in its infancy, but its application effect in various domestic fields is very good. In the education industry, 3D printing has been added to the design of textbooks.

In the field of lighting design, 3D printing requires students to master both basic design knowledge and higher practical ability. Although the current teaching level of 3D printing in schools is limited, with the continuous development of electronic technology and material technology, more forms of 3D printing equipment and materials will inevitably be used in classroom teaching in the future.