Application of jewelry 3D printer in gold jewelry field

In recent years, 3D printing technology has developed rapidly, and breakthroughs have been made in the innovative application of gold jewelry and other professional fields. The combination of 3D printing, virtual reality (VR), augmented reality (AR) and other scientific and technological means has created a favorable opportunity for the personalization, digitization and intellectualization of the gold jewelry industry. With the development of 3D printing technology in the gold and jewelry industry, through digital technology, the production process is shortened, the design inspiration is broadened, and the products show unprecedented artistic visual effects. 3D printing technology is gradually becoming the innovation engine of Intelligent Manufacturing in the gold and jewelry industry.

Gold jewelry sales is the information integration of design, display, interaction, sales, resources, technology, supply chain and other links. The traditional gold jewelry manufacturing process needs to go through many processes, such as plate making, mold pressing, waxing and mold repair. Not only is the procedure complex, but also the equipment, place, material, labor cost and time cost are large. 3D printing technology is different from traditional manufacturing methods. It is the continuation of intelligent jewelry design and digital manufacturing. Traditional manufacturing belongs to "material reduction manufacturing", while 3D printing technology is "material addition manufacturing". It is a technology that uses metal or plastic and other related materials to form objects by accurately adding materials layer by layer according to the computer digital model.

The development of 3D printing technology in the gold and jewelry industry has impacted the traditional jewelry production mode. At present, there are mainly two technical solutions for 3D printing applied to the jewelry industry:

One is the 3D printing technology that directly prints out precious metal entities, i.e. laser sintering technology. It is an additive manufacturing process based on 3D CAD design. A 3D CAD file is used as a digital information source and energy setting. It is a technical scheme to sinter a very small metal powder layer into a three-dimensional component through a high-power laser beam.

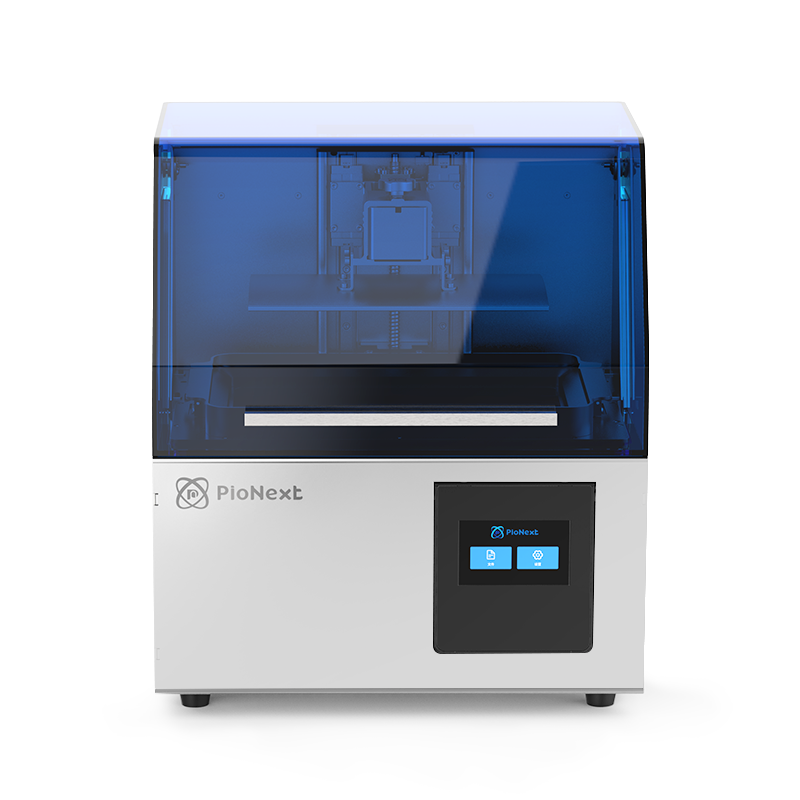

The other is to use 3D printing wax mold (projet Technology) and resin mold (LCD / DLP / SLA Technology) and adopt the lost wax casting process. This scheme improves the speed and accuracy of the most critical wax mold manufacturing process in the traditional jewelry manufacturing process, and can achieve rapid mass production. Whether 3D printing technology is directly or indirectly used in jewelry manufacturing, it will simplify the current jewelry production process and promote the development of the industry towards personalized, refined, digital and intelligent manufacturing.

3D printing precious metals (SLM technology / SLS Technology) technology is mainly used in high value-added fields such as aerospace, high-precision and cutting-edge manufacturing industries. Directly printing jewelry with expensive precious metal 3D printer has low cost performance and is not suitable for large-scale mass production.

Therefore, at present, the jewelry industry mainly applies the 3D printing wax pattern technology. The wax loss casting process is adopted, and the process accuracy can reach the micron level. Through professional 3D design software system, online interactive system, material library, model library, display platform, etc., we can use the data library resources in the system to independently select and design jewelry and quickly generate product elements. After the product orders are generated, we can print them into wax patterns using high-resolution 3D printers, Then the wax loss casting process is used for production, which can restore the design style and quickly respond to the market demand.

Advantages of 3D printing in gold and jewelry industry

The digital production is exquisite and accurate, which solves the manufacturing problem of complex structure. Compared with traditional manufacturing, complex structures cannot be completed by hand. 3D printing technology can make up for this artificial "hard injury". 3D printing technology uses computer technology to establish three-dimensional models and import the system into digital production according to the demand. It can rapidly produce high-precision and complex process jewelry that cannot be realized by traditional manufacturing, which is conducive to developing advanced customization, seizing the high-end market and improving customer satisfaction.

Reduce labor and production costs. 3D printing omits relevant steps such as prototype manufacturing and mold manufacturing, greatly reduces the production period and material cost, and has the advantages of simple operation, rapid prototyping, high precision, saving raw materials and reducing losses. At the same time, 3D scanning and CAD reverse design software cooperate to greatly improve the design efficiency, and can also quickly iterate and improve the product competitiveness.

Shorten the production cycle and respond to the market quickly. The traditional jewelry manufacturing industry is slow to respond to market changes. The supply chain generally takes 5 to 10 months to respond to the market heat. The hot search point of the Internet is fleeting. Using the big data and 3D lightweight browsing technology, customers can place orders through the online customization platform system. Through the establishment of 3D models, the data deviation can be modified in real time, the rendering effect can be confirmed, and the 3D printing technology can be used to rapidly produce and market, which truly realizes zero inventory sales.

Greatly improve the intelligent production level of the jewelry industry chain. 3D printing technology reduces the compression of flattened links in jewelry design and production, and reduces the time and cost of jewelry design and production. At the same time, VR technology can enable consumers to better experience jewelry. Through ar hardware sensors and human-computer interaction technologies, samples can be confirmed through virtual fitting, and 3D printing can be rapidly mass produced.

Development prospect of 3D printing in gold and jewelry industry

In the gold and jewelry industry, technology is still regarded as a powerful tool. It is complementary to traditional jewelry technology and jewelry design. The combination of jewelry and technology, following the three essential principles of "openness, compatibility and sharing", will explore and research the development space of intelligent jewelry in the future with advanced technology and innovative materials.

At present, the gold jewelry industry has entered the era of information and intelligent big data. With the deep integration and development of "big data + gold jewelry", it is imperative to improve the production and management concept of traditional gold jewelry enterprises and promote the industry to develop more qualitatively, and open a new chapter in the gold jewelry industry. A series of innovations brought by 3D printing to the design and production of gold and jewelry have effectively stimulated the innovation potential of gold and jewelry enterprises, enhanced the innovation value, reduced the innovation cost, and formed new competitive advantages. It is of great significance to the supply side structural reform of the jewelry industry. It will become a new driving force for the development of the jewelry industry, promote the intelligent production of jewelry enterprises, and lead the transformation and upgrading of the traditional gold and jewelry industry